Determining the Effect of Preheating Bolsters on Die Performance

Abstract

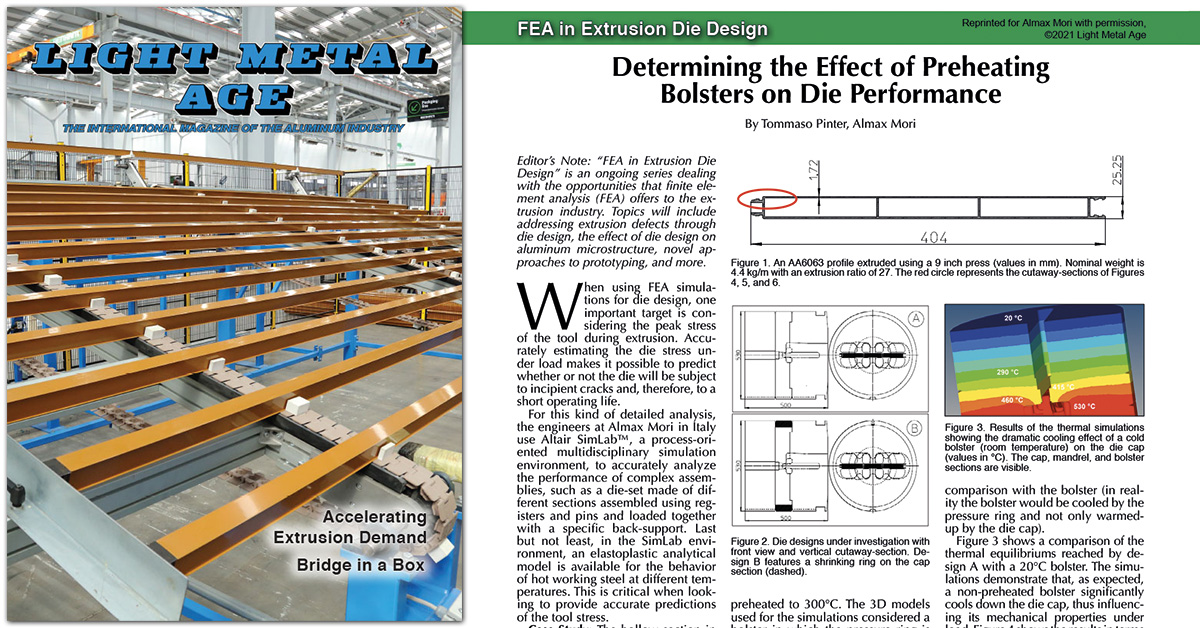

When using FEA simulations for die design, one important target is considering the peak stress of the tool during extrusion. Accurately estimating the die stress under load makes it possible to predict whether or not the die will be subject to incipient cracks and, therefore, to a short operating life. For this kind of detailed analysis, the engineers at Almax Mori in Italy use Altair SimLab‚Ñ¢, a process-oriented multidisciplinary simulation environment, to accurately analyze the performance of complex assemblies, such as a die-set made of different sections assembled using registers and pins and loaded together with a specific back-support. Last but not least, in the SimLab environment, an elastoplastic analytical model is available for the behavior of hot working steel at different temperatures. This is critical when looking to provide accurate predictions of the tool stress.